Density and concentration meter

It’s good to know what’s inside. Permanent testing and monitoring of substances flowing through is essential in order to guarantee constant product quality. Density and concentration measuring instruments from Bopp & Reuther Messtechnik stand not only for outstanding workmanship but also for durability, freedom from maintenance and the utmost precision of measurements in a wide range of applications.

Application:

Continuous monitoring of density, mass flow measurement, fiscal measurements, quality control, monitoring of waste water, product recognition, dosing, injection or blending of additives, control of chemical reactions, measurement of concentrations, monitoring and control of distillation, filtration, sedimentation, mixing or fermentation processes, process control, measurement of solid percentages in liquids, measurement of foams and suspensions etc.

Technical data

| Nominal size | DN6 to DN50 (1/8“ bis 2“) |

| Process connection | Flanges or Swagelok, sanitary threads, sterile fittings |

| Material | Stainless steel, Hastelloy, Tantalum, Monel, Inconel, 304L |

| Density range |

400 to 3,000 kg/m³ |

| Accuracy | up to ±0.01% (0,1 kg/m³ depending on model) |

| Process temperature |

-40°C to +210°C |

| Process pressure | up to 300 bar (4,351 psi) |

| Output | current output, frequency output, RS232 |

| Ex-protection | Flame proof or intrinsically safe |

Characteristics

- high repeatability

- maintenance-free

- high long-term stability

Special features

- special calibrations within the required density range

- custody transfer metering for DIMF 1.3 (Evaluation certificate)

- also useable for highly aggressive liquids, pastes and foams

- output signals scalable for density and concentration

- materials: stainless steel, Hastelloy, Tantalum, Monel, Inconel etc.

- 400- points correction table for customer specific parameterisation

Our products

DIMF 1.3

Application:

The liquid density sensor of the DIMF series is used for continuous measurement of the density / concentration of liquids or liquid mixtures. The proven tuning fork principle guarantees a high measuring accuracy with very good long-term stability. The robust design ensures reliable operation even under harsh operating conditions.

Technical Data

| Nominal size | 10mm |

| Process connection |

Internal thread G ¼ ISO 228 Flanges DN10 according to pressure stage PN 40 (or Class 150/300 RF) according to DIN 2501 (or ANSI B 16.5) Other pressure ratings available on request |

| Material | Special alloy NiFeCr and 1.4571 / 316 Ti |

| Density range | 400 to 3000 kg/m³ (24.97 Ib/ft³ to 187.28 Ib/ft³) |

| Calibration range | 400 to 1450 kg/m³ (24.97 Ib/ft³ to 90.52 Ib/ft³) |

| Accuracy | up to ±0.01% (±0.1 kg/m³ – ±0,22 Ib/ft³) |

| Repeatability | up to ±0.005% (±0.05 kg/m³ – ±0.11 Ib/ft³) |

| Process temperature | -40°C to +100°C (-40°F to + 212°F) |

| Process pressure | 100 bar (1450 psi) |

| Output | With transmitter electronics: 2-wire current output 4-20mA for operating density, reference density, concentration, °Brix, °Plato or other quantities derived from densityWith preamplifier: Vibration frequency modulated to output current and output of the medium temperature by PT100 in 4-wire technology or by 4-20 mA transmitter for evaluation by an external flow or density computer (e.g. series UR 06). |

| Ex-protection | Flame proof or intrinsically safe |

Special features

- high measurement accuracy

- 2-wire technology

- special alloy of NiFeCr and 1.4571

- Measurement independent of flow rate

- Version without seals

- material certificates

Characteristics

- direct measurement of density, reference density or concentration

- quality monitoring of liquid media in all industrial sectors.

- indirect mass measurement Connection with corresponding volume counters and corrector calculators.

- usable in custody transfer applications

- very robust construction

- low installation costs

- Measurement of almost all pumpable non-aggressive liquids or liquid mixtures, especially hydrocarbons

- Oil and Gas

- Chemistry and pharmaceutical

- Food and beverage

- Energy and power plants

- Shipbuilding

DIMF 2.0

Application:

The liquid density sensor of the DIMF series is used for continuous measurement of the density / concentration of liquids or liquid mixtures. The proven tuning fork principle guarantees a high measuring accuracy with very good long-term stability. The robust design ensures reliable operation even under harsh operating conditions.

Technical data

| Nominal size | 10mm |

| Process connection |

Internal thread G ¼ ISO 228 Flanges DN10 according to pressure stage PN 40 (or Class 150/300 RF) according to DIN 2501 (or ANSI B 16.5) Other pressure ratings available on request |

| Material | Special alloy NiFeCr and 1.4571 / 316 Ti |

| Density range | 400 to 3000 kg/m³ (24.97 Ib/ft³ to 187.28 Ib/ft³) |

| Calibration range | 400 to 1450 kg/m³ (24.97 Ib/ft³ to 90.52 Ib/ft³) |

| Accuracy | up to ±0.02 % (±0.2 kg/m³ – ±0,22 Ib/ft³) |

| Repeatability | up to ±0.005 % (±0.05 kg/m³ – ±0.11 Ib/ft³) |

| Process temperature | -40°C to +150°C (-40°F to + 302) ((on request up to +210°C (+410°F)) |

| Process pressure | 100 bar (1450 psi) (160 bar / 2321 psi on request) |

| Output | With transmitter electronics: 2-wire current output 4-20mA for operating density, reference density, concentration, °Brix, °Plato or other quantities derived from densityWith preamplifier: Vibration frequency modulated to output current and output of the medium temperature by PT100 in 4-wire technology or by 4-20 mA transmitter for evaluation by an external flow or density computer (e.g. series UR 06) |

| Ex-protection | Flame proof or intrinsically safe |

Special features

- high measuring accuracy

- 2-wire technology

- special alloy of NiFeCr and 1.4571

- Measurement independent of flow rate

- Version without seals

- material certificates

Characteristics

- direct measurement of density, reference density or concentration

- Quality monitoring of liquid media in all industrial sectors.

- Indirect mass measurement Connection with corresponding volume counters and corrector calculators

- very robust construction

- low installation costs

- Measurement of almost all pumpable non-aggressive liquids or liquid mixtures, especially hydrocarbons

- Oil and Gas

- Chemistry and pharmaceutical

- Food and beverage

- Energy and power plants

- Shipbuilding

DIMF 2.1

Application:

The liquid density sensor of the series DIMF is used for continuous measurement of the density / concentration of liquids or liquid mixtures. The proven tuning fork principle guarantees a high measuring accuracy with very good long-term stability. The robust design ensures reliable operation even under harsh operating conditions.

Technical data

| Nominal size | 25mm |

| Process connection | DN 25 PN 40 according to DIN EN 1091 DN 50 PN 40 according to DIN EN 1091 (or Class 150/300 RF ANSI B16.5) |

| Material | stainless steel 1.4571 / 316 Ti |

| Density range | 400 to 3000 kg/m³ (24.97 Ib/ft³ to 187.28 Ib/ft³) |

| Calibration range | 400 to 1450 kg/m³ (24.97 Ib/ft³ to 90.52 Ib/ft³) |

| Accuracy | better than ±0.02% (±0.2kg/m³ – ±0.044 Ib/ft³ ) |

| Repeatability | besser als ±0.005% (±0.05kg/m³ – ±0.11Ib/ft³) |

| Process temperature | -40°C to +150°C (-40°F to + 302°F) |

| Process pressure | 40 bar (580.15 psi) |

| Output | With transmitter electronics: 2-wire current output 4-20mA for operating density, reference density, concentration, °Brix, °Plato or other quantities derived from density As well as output of the medium temperature by PT100With preamplifier: Vibration frequency modulated to output current and output of the medium temperature by PT100 in 4-wire technology for evaluation by an external flow or density computer (e.g. series UR 06). |

| Ex-protection | Flame proof or intrinsically safe |

Characteristics

- direct measurement of density, reference density or concentration

- Quality monitoring of liquid media in all industrial sectors

- Indirect mass measurement in connection with corresponding volume counters and flow computer

- very robust construction

- low installation costs

- Measurement of almost all pumpable media

Special features

- high measuring accuracy

- 2-wire technology

- Measurement independent of flow rate

- Version without seals

- material certificates

- Oil and Gas

- Chemistry and pharmaceutical

- Mechanical and plant engineering

- Food and beverage

- Energy and power plants

- Shipbuilding

DIMF Compact

Application:

Density measurement and / or concentration measurement for process control or quality monitoring of liquid media in many industrial sectors.

Technical Data

| 7Nominal size | Smallest inside diameter 2 x 7 mm |

| Process connection | Internal thread G ¼” via quick mounting block |

| Material | Stainless steel 1.4571 / 316 Ti |

| Density range | 500 up to 1500 kg/m³ (1102.31 Ib/ft³ to 3306.93 Ib/ft³) |

| Accuracy | up to ±0,1% (±1kg/m³ – ±2.20 Ib/ft³) |

| Repeatability | up to ±0.02% (± 0.2kg/m³ – ±0.50044 Ib/ft³) |

| Process temperature | 0°C to +80°C (32°F to 176°F) |

| Process pressure | 6 bar |

| Output | Supply 24V Output of density and temperature values via RS232 or UART interface |

| Ex-protection | no |

Special features

- Cost-effective proven device

- Digital output of operating density and temperature – Measurement independent of flow rate

Characteristics

- Direct measurement of density and medium temperature

- Very robust construction

- Low installation costs

- Chemistry and pharmaceutical

- Mechanical and plant engineering

- Food and beverage

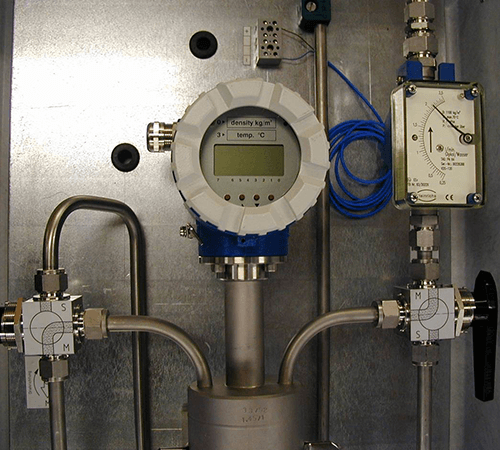

Density measuring device

Application:

Demanding measuring tasks require special density measuring equipment, adapted to the requirements of our customers. For this purpose, customer-specific solutions are tailor-made.

The density measuring device of the series DIMF is used for the continuous measurement of the density / concentration of liquids or liquid mixtures. It can also be used for product change detection, e.g. in multi-product pipelines. The proven tuning fork principle guarantees a high measuring accuracy with very good long-term stability.

Technical data

| Nominal size | 10mm |

| Process connection |

Swagelok-fitting 12mm flanges DN15 or DN25 corresponding to pressure range PN 40 (or Class 150/300 RF) to DIN 2501 (or ANSI B 16.5) other pressure ranges available on request |

| Material | stainless steel |

| Density range | 0 to 5000 kg/m³ (0 to 11023.11Ib/ft³) |

| Calibration range | 400 to 2000 kg/m³ (881.85 Ib/ft³ to 4409.25 Ib/ft³) |

| Accuracy | Better than ±0.01% (±0.1 kg/m³ – ±0,22 Ib/ft³) / ±0.02% (±0.2 kg/m³ – ±0,44 Ib/ft³) depending on device model |

| Repeatability | better than ±0.005% (±0.05kg/m³ – 0,11Ib/ft³) |

| Process temperature | -25°C to +60°C (-13°F to 140°F) |

| Process pressure | 100 bar depending on version |

| Output |

with transmitter: with preamplifier: |

| Ex-protection | intrinsically safe |

Special features

- high measuring accuracy

- custody transfer possible

- integrates DIMF1.3 or DIMF2.0 optionally with transmitter or preamplifier

- completely piped unit with integrated flushing connections

- with integrated flow control optionally also monitored

- Measuring device optionally in protective housing or on mounting plate

- with tube stand or wall mounting

- Optional strainer, manometers, pumps, heating and other customer requirements on request

Characteristics

- direct measurement of density, reference density or concentration

- Quality monitoring of liquid media in all industrial sectors

- Indirect mass measurement in conjunction with corresponding volume counters and corrector calculators

- Measurement of almost all pumpable media

- Oil and Gas

- Chemistry and pharmaceutical

- Mechanical and plant engineering